Tool steel with very good qualities as to hardness and toughness due to its high content of nickel. Good polishing, photoetching and erosion qualities

Applicability Through hardened inserts for plastic injection moulds, bending tools, pressure pads of bevelling tools, shear blades

Supply Length 500 and 1030 mm with machining allowance, in plate form with square cross section and square dimensions, soft annealed, max. 285 HB (max. 965 N/mm2)

Heat Treatment Data Stress-relief annealing 600 - 650 °C

Soft annealing 620 - 650 °C Hardening 840 - 870 °C

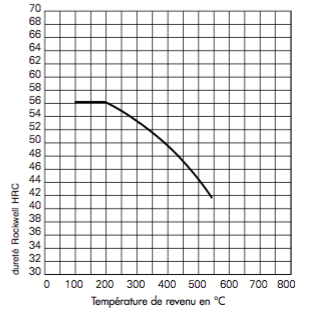

Quenching Oil, air or warm bath Tempering 170 - 190 °C